SMALL SCALE AND MEDIUM-TO-LARGE SCALE MINERAL PROCESSING EQUIPMENT

COST EFFECTIVE AND EFFICIENT SOLUTIONS FOR ALLUVIAL, ELUVIAL, HARD ROCK, TAILINGS AND COMBINATIONS OF FEED TYPES. APT SPECIALISE IN GRAVITY CONCENTRATION, CYANIDATION AND FLOTATION SYSTEMS.

SMALL SCALE processing EQUIPMENT

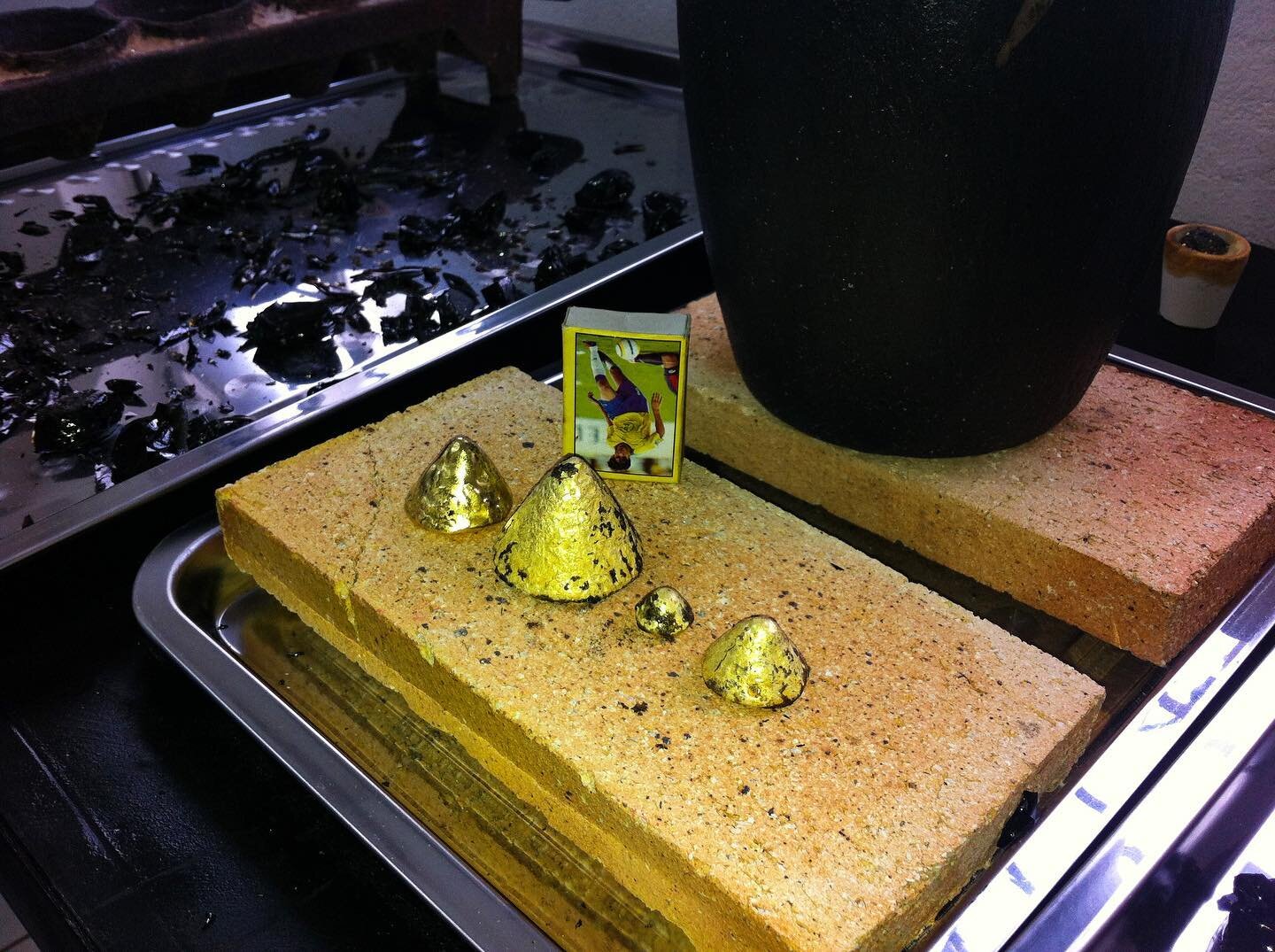

GoldKacha Concentrator

GoldMasta Sluice

GoldTrail Small Mobile Concentrator (for Quadbike)

RG Scrubber (mobile or frame mounted)

Hard Rock Plant (mobile or frame mounted)

TriTank/TriFloat

Elu-X Carbon Elution/Electrowinning

and more

MEDIUM TO LARGE SCALE processing EQUIPMENT

GK-X Concentrator

RG Scrubber (10tph through to 150tph)

Hard Rock Plants (10tph through to 150tph)

RG Oxide Plants (Alluvial and Hard Rock)

TriTank/TriFloat

Elu-X Carbon Elution/Electrowinning

Field Assay Laboratories

and more

“The APT small scale Groundbreaker Equipment for gold recovery in field is second to none worldwide. I recommend APT equipment for durability and efficiency, having used this equipment in tough African conditions with no issues.”