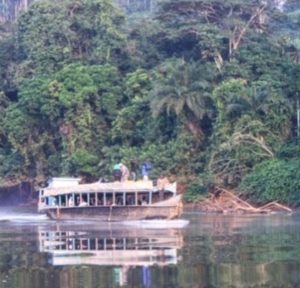

We have been asked time and again if the GoldKacha can really be used optimally in remote regions and the answer is always yes! It can, and this has been proven time and again. Pictured here is a GoldKacha processing facility on a river in Central Africa, still in operation 5 years on. We thank our clients for their valued and continued support.

One client said of APT's mining equipment "I have used APT's GoldKacha on a variety of alluvial projects in the most adverse and remote locations and they have proven themselves time again to be the ideal units for excellent recoveries in a multitude of applications. With their low operating costs and used in conjunction with their other plants, the GoldKacha has been instrumental for assessing alluvial deposits and exploration. They are a must in any miners tool kit". It's great to receive feedback from clients on our previous installations.

Do you have any questions or feedback on the APT GoldKacha or any other piece of mining equipment and their use in remote regions? Email us on info@aptprocessing.com and we will be happy to answer them for you. Our focus is on small to large scale modular mineral processing plants and this field is where we thrive!