Whether you are an artisanal miner looking to break into the market on a budget, or an investor looking to do some exploration before your next big spend, the APT GoldKacha will most likely earn a place somewhere in your mineral processing plan. The APT GoldKacha is a centrifugal gravity mineral concentrator, designed as part of APT’s Groundbreaker and Exploration range. It was developed especially for small mining applications and is ideal for gold prospecting. The novel centrifugal riffle principle results in high recovery of both coarse & fine precious metals, particularly fine gold recovery.

Need a quick breakdown? This is how it works. Slurry is fed into the GoldKacha over a limiting size screen of 3mm. Material within the desired size range falls into the spinning cone and the heavier precious metals and minerals are forced outward and become trapped within the riffles. The concentrating action is enhanced by a unique and patented reflux principle, resulting in several concentrating stages on the ore before it exits. The concentrate is purged approximately once every hour and collected for further upgrade using a process such as conventional gold panning or our highly effective GoldKonka Concentrate Upgrader. The concentrator is driven by an electric 0.75kW motor, which can be connected to a small generator to allow for operation in remote areas.

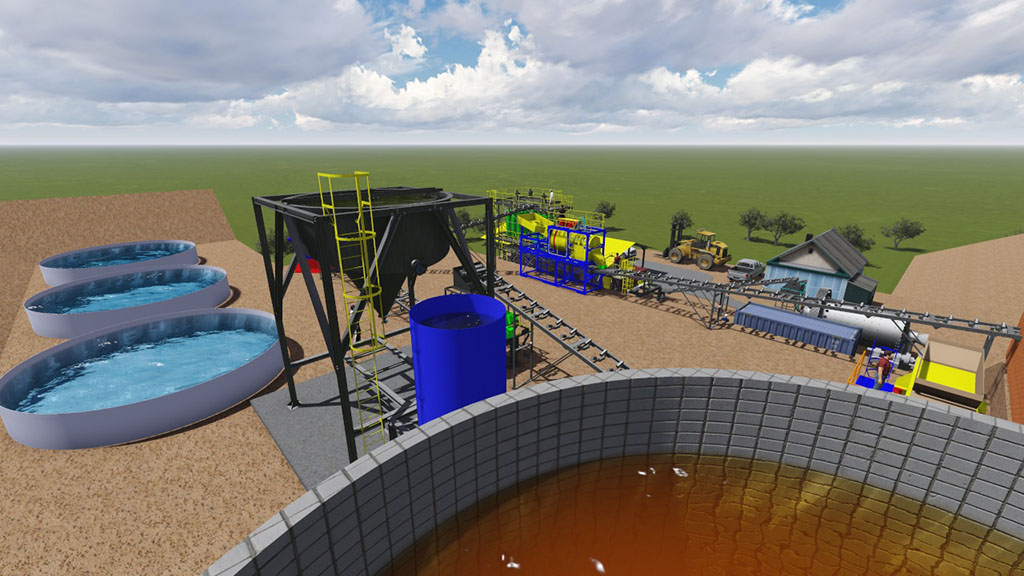

The GoldKacha can handle a capacity of up to 3tph, but if you’re looking for a larger solution, several units can be nested allowing one operator to treat a greater tonnage of material, as shown in the picture below.

Similarily, for those big on business, several GoldKacha concentrators can be implemented as a custom treatment facility, where the owner can hire them out to enable others to process their own material in a safe & simple way. We will assist in performing demonstrations, should you wish, that show just how simple this plant is to operate, and how effective it is in recovery.

If you’re not sure if the GoldKacha is right for your ore, you can submit a sample for testing which will be undertaken alongside our associate mineral testwork laboratory, Peacocke & Simpson, who are ISO9001:2008 certified and have been in business since 1985. Here at APT, we provide an entire range of equipment available as add-ons so that we can give you the perfect processing plan. Hard rock or alluvial, course or fine, we’ve got you covered. Check out the rest of our Groundbreaker Range here: small-scale stand-alone Jaw Crusher JC25, hard rock RD15 Fines Grinder, GoldKonka and GoldMasta sluice.

It is not too well known that APT does, in fact, allow distributors to become part of our sales team and get the plants to regions which we cannot, so if you are interested in becoming a distributor of the GoldKacha or any other pieces from the Groundbreaker Range, contact us at info@aptprocessing.com. We look forward to hearing from you!