APT has begun 2016 by establishing, in association with their active agents in East Africa, Borassus, a number of 100% mercury free gold processing plants. The efficiency of this particular method of processing is attracting intense local interest from local artisanal miners. Interested miners have queued for as long as 48 hours at demonstrations of the plants and process. Opinion has been strongly expressed by these miners that the recovery rate is far higher with APT’s 100% mercury free, processes, than from traditional methods. The plants used in the process consist of simple dry or wet milling utilizing a GoldKacha Concentrator and a GoldMasta sluice, to optimise free gold recovery. Concentrate recovered by this process, can then be upgraded by using a GoldKonka, finally smelted using a field smelter, which is run off the same power source.

Following the success of the East African demonstration of this process, APT plans to launch this process globally. The significance of APT’s 100 percent mercury free process in an increasing environmentally fragile world cannot be over stressed.

APT welcome enquiries from all interested parties included listed mining entities with environmental concerns, philanthropists, environmentalists, small and large mining concerns.

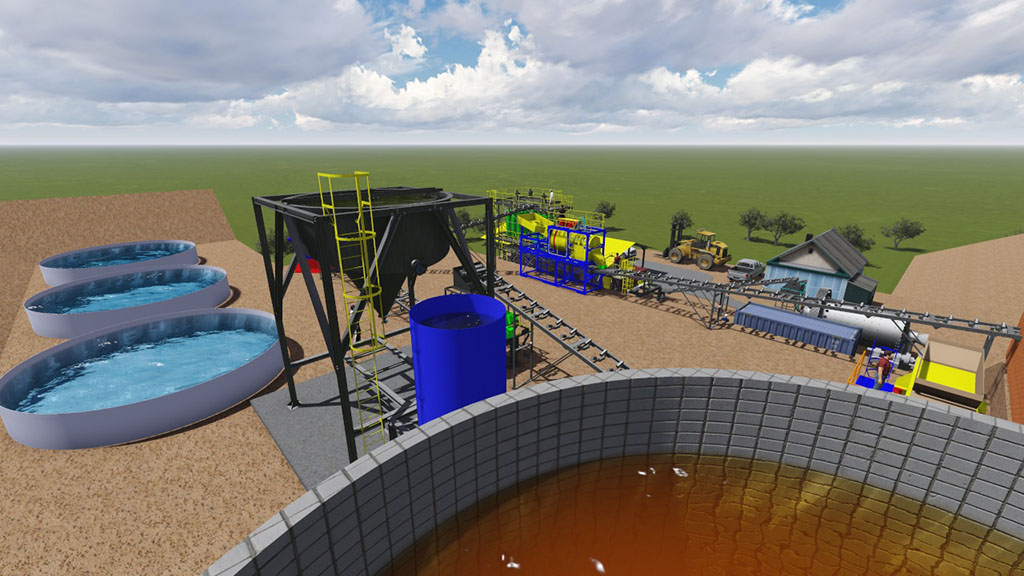

An existing APT equipped 100% mercury free gold proceeding plant site. Each site can service 200 to 300 artisanal miners.

Currently a 48 hour waiting line. Artisanal miners determined to get better recovery are prepared to wait. This waiting interval is being addressed and centres are currently being expanded and replicated regionally & rapidly.